Understanding Rice Mill Costs in India: A Comprehensive Guide

India, being one of the largest producers and consumers of rice globally, has a well-established rice milling industry. The demand for rice mill machinery and plants has been on the rise due to the increasing need for processed rice in both domestic and international markets. If you’re considering investing in a rice mill in India, understanding the associated costs is crucial for making informed decisions. This guide delves into the various factors influencing Rice Mill Cost India, the types of rice mill machinery available, and how to choose the right equipment for your needs.

Factors Influencing Rice Mill Costs in India

1. Scale of Operation

The size and capacity of the rice mill significantly impact the overall cost. Small-scale mills with a capacity of 1-2 tons per hour (TPH) are more affordable, whereas large-scale mills with capacities exceeding 10 TPH require a higher investment due to the complexity and scale of operations.

2. Type of Rice Mill

There are primarily two types of rice mills:

-

Modern Rice Mills: These are fully automated and require a higher initial investment but offer higher efficiency and lower operational costs.

-

Traditional Rice Mills: These are semi-automated and have a lower initial cost but may incur higher operational costs due to manual labor and lower efficiency.

3. Machinery and Equipment

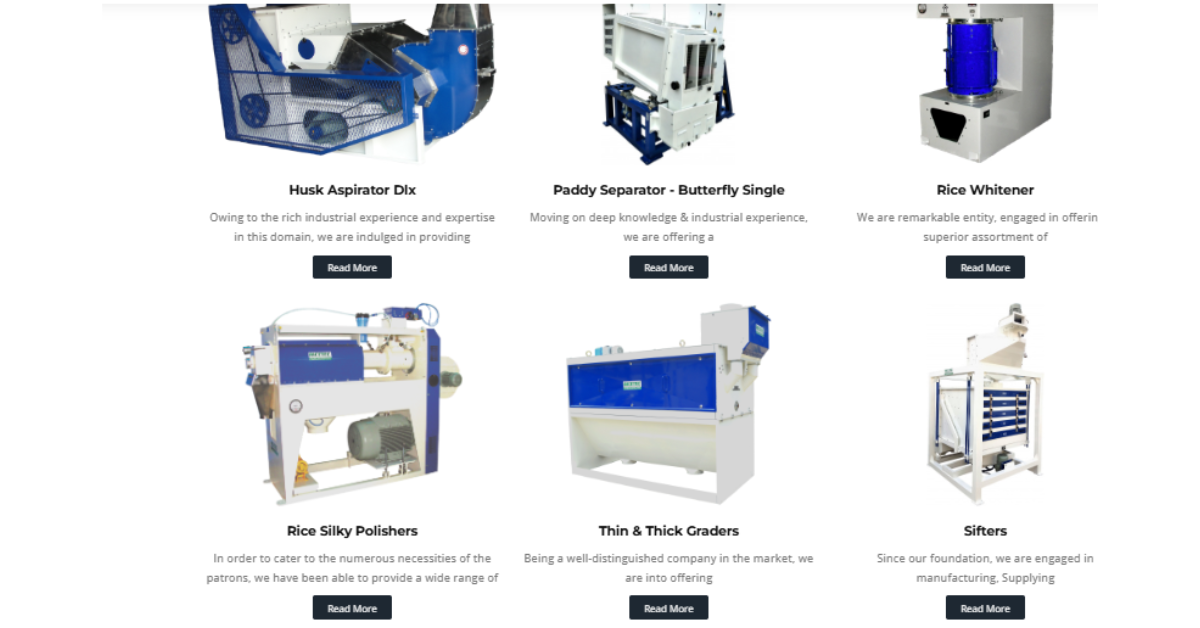

The cost of machinery is a significant component of the total investment. Key equipment includes:

-

Pre-Cleaners: Used to remove impurities from paddy before milling.

-

De-Stoners: Remove stones and other heavy impurities.

-

Shellers: Separate husk from rice.

-

Whitener and Polisher: Enhance the appearance and quality of rice.

-

Separators and Graders: Classify rice based on size and quality.

The quality, brand, and automation level of these machines influence their cost.

4. Infrastructure and Installation

Setting up a rice mill involves constructing or leasing a facility, installing machinery, and ensuring proper power and water supply. The location of the mill also affects costs due to transportation and logistics.

5. Labor and Operational Costs

Labor costs in India are relatively low, but skilled labor is essential for operating modern rice mills. Additionally, ongoing costs like electricity, maintenance, and consumables should be considered.

6. Regulatory and Licensing Fees

Obtaining necessary licenses and adhering to local regulations involve costs that vary by state and region.

Estimated Cost Breakdown

| Component | Estimated Cost (INR) |

|---|---|

| Small-Scale Mill (1-2 TPH) | 15,00,000 – 25,00,000 |

| Medium-Scale Mill (5-6 TPH) | 50,00,000 – 75,00,000 |

| Large-Scale Mill (10+ TPH) | 1,00,00,000 – 2,50,00,000 |

| Land and Infrastructure | 20,00,000 – 50,00,000 |

| Licensing and Miscellaneous | 5,00,000 – 10,00,000 |

Note: These are approximate costs and can vary based on location, machinery brand, and other factors.

Choosing the Right Rice Mill Machinery

Selecting the appropriate machinery is crucial for the efficiency and profitability of your rice mill. Consider the following:

-

Capacity Requirements: Choose machinery that aligns with your expected throughput.

-

Automation Level: Fully automated systems reduce labor costs and improve consistency.

-

Energy Efficiency: Opt for machines that consume less power to reduce operational costs.

-

Maintenance and Support: Ensure that the manufacturer provides adequate after-sales support and spare parts availability.

Financing Options for Rice Mill Setup

Setting up a rice mill requires significant capital investment. Various financing options are available:

-

Bank Loans: Many banks offer loans for setting up agro-based industries.

-

Government Schemes: The Indian government provides subsidies and financial assistance for agro-processing units.

-

Private Investors: Partnering with investors can provide the necessary capital.

Conclusion

Investing in a rice mill in India can be a profitable venture given the country’s vast rice production and consumption. However, it’s essential to consider all associated costs and factors before making a decision. By understanding the various components that contribute to the overall cost, you can make informed choices that align with your business objectives.

Frequently Asked Questions (FAQs)

1. What is the minimum investment required to set up a rice mill in India?

The minimum investment varies based on the scale of operation. For a small-scale mill (1-2 TPH), the investment can start from approximately INR 15 lakhs, excluding land and infrastructure costs.

2. Are there any government subsidies available for setting up a rice mill?

Yes, the Indian government offers various subsidies and financial assistance schemes under the Ministry of Food Processing Industries (MoFPI) and state-specific schemes to promote agro-processing industries.

3. What is the expected return on investment (ROI) for a rice mill?

The ROI depends on factors like mill capacity, operational efficiency, and market demand. On average, investors can expect a payback period of 3-5 years.

4. How much land is required to set up a rice mill?

The land requirement depends on the scale of the mill. A small-scale mill may require 1-2 acres, while larger mills may need 5 acres or more.

5. What are the key maintenance requirements for rice mill machinery?

Regular maintenance includes cleaning, lubrication, and timely replacement of worn-out parts. It’s essential to follow the manufacturer’s maintenance guidelines to ensure optimal performance.

Final Thoughts

Setting up a rice mill in India is a promising business opportunity, given the country’s position as a major rice producer. By carefully considering the associated costs and factors, and choosing the right machinery and scale of operation, entrepreneurs can establish a successful rice milling business. Always conduct thorough research and consult with industry experts to make informed decisions that align with your business goals.